Understanding Value Added Analysis in Business Process Management (BPM)

In the constantly changing landscape of business, efficiency and effectiveness walk together in successful operations. This is where Value Added Analysis steps into the spotlight. An important tool in Business Process Management (BPM) is Value Added Analysis that studies business processes through a micro angle lens that focuses on what truly matters and most impact the customer’s perception.

Why Value Added Analysis Matters?

At its core, Value Added Analysis is about impact. It asks a fundamental question: How does an activity or process positively affect the customer’s experience

Unlike traditional methods that may prioritize a company’s internal metrics, this technique zeroes in on customer-centric outcomes. It’s not about what feels right; it’s about what actually delivers.

The benefits of Value Added Analysis are manifold:

- Value Identification: It distinguishes the actions that enhance your product or service.

- Efficiency Mapping: It spots inefficiencies or superfluous activities ripe for optimization or removal.

- Continuous Improvement: It fosters an environment where processes are regularly refined.

- Informed Decision-Making: It ensures decisions are made with data-driven insights.

How to Perform a Value Added Analysis?

Embarking on a Value Added Analysis involves a series of structured steps:

Process Identification: Catalog all activities and processes within your organization.

- Cost Calculation: Assign a cost to each identified activity or process.

- Value Assessment: Gauge the value each activity or process generates.

- Value-Cost Comparison: Measure the generated value against the incurred cost.

- Prioritization: Spotlight the areas with the highest and lowest value addition for targeted improvement.

The Concept of Value-Hour

Central to this analysis is the ‘value-hour’—a metric that represents the cost of resources expended in an hour-long activity. This number is crucial; it’s the basis to efficiency, highlighting both productive endeavors and costly spending time.

Pioneers in Value Addition: Companies Leading by Example

In the business world, the adoption of Value Added Analysis as a fundamental strategic is not just limited to a select few—it’s a practice embraced by many successful organizations. Here’s a look at some well-known companies that have integrated value addition into their core business strategies:

Amazon: The Customer Obsession Model

Amazon stands as a testament to the power of customer-centric value addition. From its user-friendly interface to its Prime delivery system, every process is optimized to add value to the customer’s experience. By continuously analyzing and improving their processes, Amazon ensures that the value provided to customers is consistently growing, which in turn, propels their market dominance.

Toyota: The Lean Pioneer

Toyota’s legendary lean manufacturing system is deeply rooted in the principles of value addition. By identifying and eliminating waste through their famed ‘Kaizen’ approach, Toyota focuses on processes that directly contribute to the value perceived by the end customer. This relentless pursuit of efficiency has not only made Toyota synonymous with quality but has also revolutionized manufacturing across industries.

Apple: Innovation as Value

Apple’s strategy revolves around adding value through innovation and design. Each product cycle is an exercise in evaluating how new features or design elements can enhance the customer’s interaction with their devices. This focus on the value-added through technological advancement and aesthetics has created an unparalleled brand loyalty and market leadership.

Walmart: Cost Efficiency for Customer Value

Walmart’s commitment to providing value is reflected in its supply chain and operational efficiencies. By optimizing these processes, Walmart is able to offer lower prices to customers, which is a direct form of value addition in the retail sector. Their strategy demonstrates how operational cost savings can be passed on as value to customers.

Starbucks: The Third Place Concept

Starbucks has redefined the coffee shop experience by focusing on ‘the third place’—a comfortable and inviting space between home and work. Their dedication to creating this experience is a strategic move to add value beyond just the coffee. The ambiance, customer service, and community feel of their stores are all part of their value-added proposition.

These companies exemplify the application of Value Added Analysis in diverse ways, tailored to their specific industries and customer bases. They show that adding value isn’t just about a single factor—it’s about considering every facet of the customer experience and continuously seeking improvements. By placing customer value at the forefront, these organizations not only excel but also redefine the standards in their respective fields.

Quality: The Keystone of Process Management and Value Addition

In the sphere of Business Process Management (BPM), quality is not just a measure of excellence—it’s the very foundation upon which processes are built and refined. Quality, in this context, is a multi-dimensional concept that extends beyond the mere absence of defects; it encompasses the features and characteristics of a product or service that bear on its ability to satisfy given needs.

The Quality-Value Interconnection

When we talk about adding value through BPM, we’re inherently talking about enhancing quality. Every step taken to improve a process is, at its core, an effort to elevate the quality of the output—whether that’s a physical product or a service rendered. Quality is the lens through which customers perceive and evaluate the value added to their experience.

Quality in Time Management

Time management is a crucial aspect of BPM and a significant component of quality. The adage ‘time is money’ rings particularly true in the business environment, where the timely delivery of products or services is often as critical as their quality. Therefore, process optimization, which seeks to minimize Lead Time, Waiting Time, and Cycle Time, must do so without sacrificing the quality of the end result.

Lead Time Quality: Reducing Lead Time should never come at the cost of quality. Instead, it should be achieved through the elimination of inefficiencies and the streamlining of operations to enhance the customer’s experience.

Waiting Time Quality: Minimizing Waiting Time can lead to a direct increase in quality by ensuring that resources are used effectively and customers receive their products or services faster. However, it’s important to ensure that this reduction doesn’t result in a rushed process where mistakes are more likely to happen.

Cycle Time Quality: Improving Cycle Time should focus on refining the process to make it more efficient without compromising the meticulous attention to detail that is often required to maintain high-quality standards.

Continuous Quality Improvement

Continuous Quality Improvement (CQI) is a principle that sits at the heart of BPM. It suggests that processes should be in a state of ongoing analysis and enhancement. The aim is to incrementally improve the quality of processes, and by extension, the quality of products and services offered to customers. This commitment to CQI is what enables organizations to maintain and increase value in a competitive market.

The Cumulative Impact of Quality on Value

It’s essential to recognize that quality improvement is not just about the final product. Every stage of the process contributes to the cumulative quality experienced by the customer. By applying Value Added Analysis with a quality-centric approach, organizations can ensure that each process not only meets but exceeds customer expectations.

In conclusion, quality is the thread that weaves together the various elements of BPM to create a tapestry of value. By prioritizing quality in process management and linking it to time and other aspects of BPM, organizations can assure that they are not only adding value but also building a reputation for excellence that is appreciated and demanded by customers. Quality is not just a metric to be achieved; it’s a philosophy to be embodied in every BPM initiative.

Decoding Time Metrics: Lead Time, Waiting Time, and Cycle Time

Time is a currency in business, and understanding how it’s spent is crucial to mastering Value Added Analysis. In BPM, three temporal metrics stand out: Lead Time, Waiting Time, and Cycle Time. Each of these metrics offers insights into how time affects value creation and customer satisfaction.

Lead Time: The Start-to-Finish Measure

Lead Time is the total time taken from the moment a process is initiated until it is completed. This is your process’s stopwatch; it starts ticking from the point of customer order or request and only stops when the final product is delivered. Lead Time is the overarching timeline that includes all activities—value-adding or not.

Waiting Time: The Hidden Cost of Inactivity

Within Lead Time hides Waiting Time—the period during which no value is being added. It’s the pause between processes, the idle machines, the lag before approvals. It’s deceptive because while no visible progress is made, costs continue to accrue. Waiting Time can be a silent saboteur, quietly decreasing efficiency and inflating costs without contributing anything to the customer.

Cycle Time: The Pulse of Productivity

Cycle Time measures how long it takes to complete one full cycle of a process, typically from the start of production to its completion. It’s the rhythm of your operations, the beat to which your processes dance. In Cycle Time, we find the purest expression of active work—where value is not just intended but actually infused into the product or service.

Example of Time Management Calculation for a Computer Maintenance Company

Let’s consider a mid-sized company specializing in computer maintenance, which we’ll name ‘TechPro Services.’ TechPro Services follows a structured process to handle maintenance requests that involves four key departments: Customer Service, Diagnostics, Repair, and Quality Assurance.

Extended Business Process Overview:

- Reception: Accepts the computer and logs it into the system.

- Customer Service: Contacts the customer with any additional questions and communicates throughout the process.

- Quotation: Assesses the computer to create a service quote.

- Payment Processing: Handles payment before service is rendered.

- Diagnostics: Technicians diagnose the computer’s issue.

- Repair: The repair team fixes the diagnosed issues.

- Quality Assurance: Tests the repaired computers to ensure they meet standards.

- Delivery: Customer is notified and the computer is handed back.

Hypothetical Time Metrics:

Reception:

- Lead Time: 1 hour from customer drop-off to logging the computer into the system.

- Cycle Time: 15 minutes to receive the computer and log it.

- Waiting Time: 15 minutes until the Quotation department evaluates it.

Customer Service:

- Lead Time: Ongoing throughout the process for communication purposes.

- Cycle Time: Varies depending on customer interaction.

- Waiting Time: N/A (as it is an ongoing support role).

Quotation:

- Lead Time: 2 hours from receiving the computer to providing a quote to the customer.

- Cycle Time: 1 hour to assess and generate a quote.

- Waiting Time: 30 minutes waiting for customer approval on the quote.

Payment Processing:

- Lead Time: 1 hour to process payment before service commencement.

- Cycle Time: 30 minutes to handle payment transactions.

- Waiting Time: 30 minutes for payment confirmation.

Diagnostics:

- Lead Time: 3 hours from start of diagnostics to repair plan formulation.

- Cycle Time: 2 hours to diagnose each computer.

- Waiting Time: 1 hour before a technician can start diagnostics (Bottleneck).

Repair:

- Lead Time: 4 hours to repair the computer and send to Quality Assurance.

- Cycle Time: 3 hours to perform the repair.

- Waiting Time: 30 minutes for parts and information handover from Diagnostics.

Quality Assurance:

- Lead Time: 2 hours to test and approve the computer for delivery.

- Cycle Time: 1.5 hours to test each computer.

- Waiting Time: 15 minutes waiting for the Repair department to finish and handover.

Delivery:

- Lead Time: 1 hour until the customer picks up the repaired computer.

- Cycle Time: 15 minutes to complete the handover process.

- Waiting Time: 45 minutes for customer arrival and handover.

Overall Time Management Calculation:

Addressing the Bottleneck:

The bottleneck is now at the Diagnostics department, with a 1-hour wait time before diagnostics can begin. TechPro Services could consider cross-training employees, utilizing diagnostic software to assist with quick assessments, or restructuring the workflow to reduce this waiting time.

By resolving the bottleneck, TechPro Services could significantly reduce the Total Waiting Time, thereby decreasing the Total Lead Time and increasing the throughput of computers serviced. This reduction in time not only adds direct value to the customer by way of faster service but also increases the company’s capacity to handle more work, thus indirectly contributing to revenue and growth.

Understanding these metrics is crucial. They’re interlinked, each affecting the other. Lead Time sets the stage, Cycle Time choreographs the process, and Waiting Time can disrupt the performance. By analyzing these metrics, organizations can pinpoint where delays happen, where time is well spent, and where it is squandered.

Time Management and the Bottleneck Concept in Lean Six Sigma and BPM

In the synergistic realms of Lean Six Sigma and Business Process Management (BPM), time management is a critical component that intersects with the concept of bottlenecks—a concept essential to both philosophies. Understanding and addressing bottlenecks is essential to streamlining processes, reducing waste, and ultimately enhancing value.

Bottlenecks: The Choke Points of Processes

Bottlenecks occur when a particular stage in a process slows down the flow of operations, creating a queue and delaying subsequent activities. Much like the narrow neck of a bottle restricts the flow of liquid, a process bottleneck restricts the flow of work. In time management terms, bottlenecks extend Lead Times and increase Waiting Times, which directly impacts Cycle Times and diminishes the process’s overall efficiency.

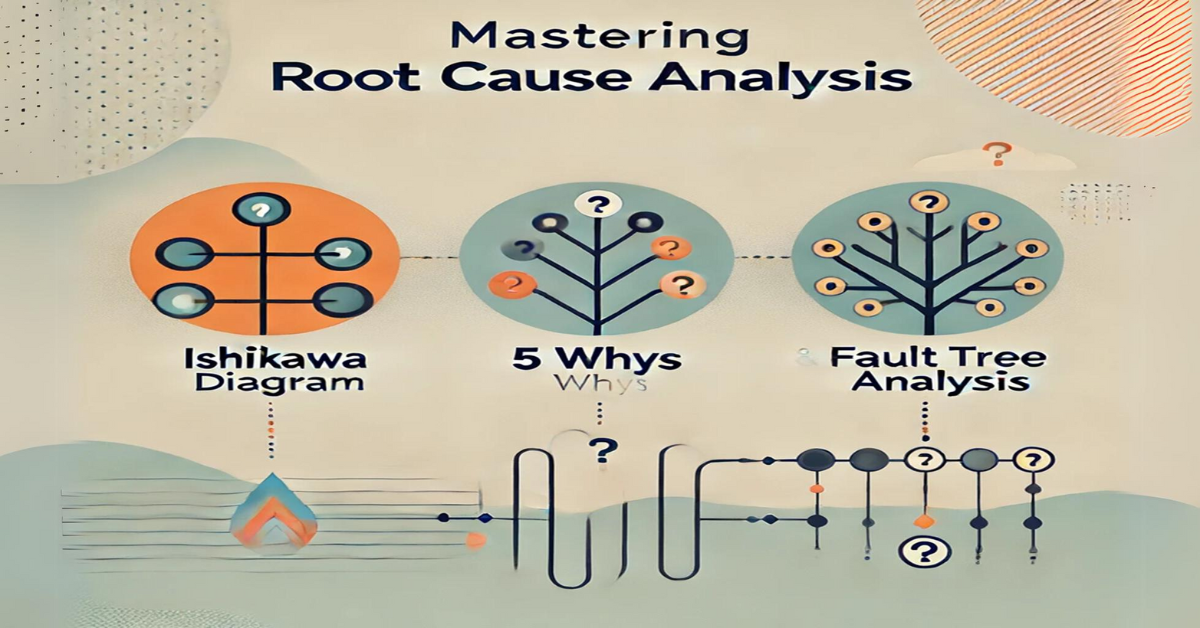

Identifying and Addressing Bottlenecks

Lean Six Sigma provides a structured approach to identifying bottlenecks through its DMAIC (Define, Measure, Analyze, Improve, Control) methodology. By defining the problem, measuring process flows, analyzing data, improving the process, and controlling the new process flow, organizations can systematically alleviate bottlenecks.

In BPM, the identification of bottlenecks is similarly critical. It involves mapping out all processes and their respective times to pinpoint where delays are occurring. Once identified, solutions can range from redistributing workloads, adding resources, or redesigning the process to smooth out the disruptions.

The Ripple Effect of Bottlenecks

The presence of bottlenecks in a process can have a cascade effect, causing delays that extend well beyond the immediate area of congestion. In a production environment, for instance, a bottleneck can lead to increased inventory costs as upstream processes continue to produce output that cannot be processed downstream. In service industries, it can result in long customer wait times, affecting satisfaction and perceived quality.

Lean Six Sigma, BPM, and the Pursuit of Flow

Both Lean Six Sigma and BPM strive for a state of ‘flow’—a smooth, efficient progression of tasks from start to finish without unnecessary interruption. Lean Six Sigma often employs tools like value stream mapping to visualize and understand the flow of materials and information, thereby identifying bottlenecks. BPM, with its broader scope, looks at process flow from a holistic perspective, seeking to optimize, automate, control and monitor processes to maintain a steady rhythm of business activities.

Time Management as a Strategy for Value Addition

Effective time management within Lean Six Sigma and BPM is about more than just speed—it’s about the strategic allocation and utilization of time resources. By managing time well and resolving bottlenecks, organizations ensure that every minute is spent adding value, either directly or indirectly, to the customer experience. This focus on time as a facet of quality management underscores its role as a driver of value in any lean or BPM-driven initiative.

In other words, the intersection of time management with the bottleneck concept in Lean Six Sigma and BPM is fundamental to driving efficiency and value. Addressing bottlenecks not only improves the flow of processes but also enhances the quality and value of the output. By doing so, organizations can deliver products and services to customers faster, better, and more cost-effectively, thereby achieving the ultimate goal of value addition.

Companies that excel in BPM don’t just track these times; they investigate them. They know that reducing Lead and Waiting Times without compromising the Cycle Time’s quality can significantly enhance value for customers. It’s this understanding of time’s role in value addition that can transform good companies into industry leaders.

Deciphering Value-Hour Costs: Fixed and Variable Expenses

In Business Process Management (BPM), when calculating the value-hour of an activity or process, it’s essential to dissect the cost structure into fixed and variable costs. This approach provides a more nuanced understanding of where and how costs are incurred, enabling businesses to pinpoint efficiency and value-adding opportunities.

Fixed Costs

Fixed costs are the expenses that do not fluctuate with the volume of work or production levels. They are the consistent expenditures that a business incurs, regardless of its operations scale.

- Salaries: Monthly wages for staff, which remain constant regardless of the number of computers serviced.

- Rent: Payments for the physical space occupied by the operation whether the facilities are bustling or not.

- Licenses: Fees for software or certifications needed to operate legally and efficiently, paid annually or monthly.

- Depreciation: The allocation of the cost of tangible assets over their useful life, such as equipment and tools used in computer maintenance.

- Insurance: The regular premiums for protecting against various business risks.

- Administration: Costs associated with management and general office upkeep, which are not directly tied to the volume of services provided.

Variable Costs

Variable costs change in direct proportion to the volume of output or the level of services provided.

- Materials: Parts and components used in the repair of computers, which vary with the number of services rendered.

- Energy: Although partially fixed, the variable component corresponds to the actual consumption related to servicing computers, such as running diagnostic equipment.

- Outsourced Services: Payments for third-party services, such as specialized repairs or software support, incurred per case.

- Cleaning and Maintenance: The cleaning supplies and maintenance of equipment, which may increase with heavier use.

Example cost calculation for ‘TechPro Services’

Let’s consider ‘TechPro Services’ is evaluating the value-hour for their Diagnostics department. They calculate the costs as follows for an average hour of activity:

Fixed Costs:

- Salaries: $25/hour (allocated portion of monthly salaries)

- Rent: $5/hour (allocated portion of monthly rent)

- Depreciation: $3/hour (allocated portion of yearly depreciation of diagnostic machines)

- Insurance: $2/hour (allocated portion of insurance premiums)

- Administration: $4/hour (allocated portion of administrative staff salaries and office supplies)

Variable Costs:

- Materials: $10/hour (average parts and components used per hour)

- Energy: $1/hour (electricity for running diagnostic tests)

- Outsourced Services: $2/hour (average cost based on service volume)

- Cleaning and Maintenance: $0.50/hour (cleaning supplies and minor equipment servicing)

Adding these costs, the value-hour for the Diagnostics department is:

$25 + $5 + $3 + $2 + $4 + $10 + $1 + $2 + $0.50 = $52.50 per hour

This value-hour gives ‘TechPro Services’ a clear picture of what it costs to run the Diagnostics department per hour, allowing them to make informed decisions on pricing, process improvements, and value optimization. By scrutinizing both fixed and variable costs, they can strategize on ways to maintain quality service while enhancing profitability and customer satisfaction.

Customer Satisfaction and Value Perception in BPM: A Strategic Approach

In Business Process Management (BPM), understanding and integrating customer feedback is crucial for refining services and aligning operational activities with client expectations. By systematically evaluating customer opinions and satisfaction, companies can make informed decisions on resource allocation and process optimization to enhance perceived value.

The Role of Customer Opinion and Satisfaction Research

Customer satisfaction research provides direct insights into what clients value most about a service. This feedback enables companies to discern which aspects of their operations truly enhance the customer experience and which may be falling short. By conducting regular satisfaction surveys, focus groups, and feedback sessions, businesses can map out customer satisfaction across various service milestones.

Concept of Activity or Milestone Abstraction

Process abstraction involves categorizing each step or milestone in a business process according to its perceived customer value. This approach helps identify:

Primary processes: These are the milestones that directly influence customer satisfaction and are perceived as high-value by customers.

Support processes: These are necessary for operational completeness but may have lower direct value perception from the customer’s standpoint.

This distinction allows companies to prioritize and adjust spending and efforts to focus more on primary business processes that drive customer satisfaction.

Applying Concepts to ‘TechPro Services’

Let’s consider our example company, ‘TechPro Services,’ which specializes in computer maintenance. By employing customer feedback mechanisms, they can determine how each department contributes to overall customer satisfaction.

In this example, we’ll detail how ‘TechPro Services’ uses customer feedback to optimize spending and resources across four critical service milestones:

Reception and Quotation, Maintenance Service, Payment, and Delivery. Each milestone will be evaluated for its perceived value to customers, guiding the allocation of resources to maximize customer satisfaction.

Initial Setup and Customer Feedback

‘TechPro Services’ conducts a comprehensive customer satisfaction survey and compiles the following insights on the perceived importance of each service milestone:

- Reception and Quotation: 20% of customers value a quick and accurate initial assessment and fast quotation delivery.

- Maintenance Service: 40% of customers prioritize the quality and speed of maintenance work.

- Payment: 10% of customers note the efficiency of the payment process as important.

- Delivery: 30% of customers emphasize the importance of prompt and secure equipment return.

The total percentages add up to 100%, providing a full view of customer priorities.

Current Resource Allocation (Before Optimization)

Reception and Quotation:

- Monthly cost: $40,000

- Staff involved: 5

Maintenance Service:

- Monthly cost: $100,000

- Staff involved: 20 technicians

Payment:

- Monthly cost: $20,000

- Staff involved: 2

Delivery:

- Monthly cost: $40,000

- Staff involved: 3

Proposed Resource Reallocation (After Customer Feedback)

Considering the customer feedback percentages, we can reallocate resources to better match customer value perception:

- Reception and Quotation (20% perceived importance):

- Reduce monthly cost to $30,000 (a 25% decrease)

- Reduce staff involved to 4 (efficiency improvements)

- Maintenance Service (40% perceived importance):

- Increase monthly cost to $120,000 (a 20% increase)

- Maintain staff but increase training and upgrade tools

- Payment (10% perceived importance):

- Reduce monthly cost to $10,000 (a 50% decrease)

- Automate more functions to require fewer human resources

- Delivery (30% perceived importance):

- Increase monthly cost to $50,000 (a 25% increase)

- Increase staff to 4 to enhance speed and security of delivery

Value-Hour Improvements Calculation

By adjusting the resources based on the customer feedback percentages, ‘TechPro Services’ aims to improve the efficiency and effectiveness of each milestone:

The reduced spending in low-impact areas (like Payment) allows for increased investment in high-value areas (like Maintenance Service and Delivery), ensuring that more resources are devoted to enhancing the aspects of the service that customers value most.

This strategic reallocation not only targets improvements in customer satisfaction but also optimizes operational efficiency, ensuring that each dollar spent contributes maximally to perceived customer value.

Convergence of Management Types

Value Added Analysis isn’t a siloed practice; it’s the nexus where all management types within BPM meet. It’s the point of convergence that brings together various disciplines, all with a shared goal of elevating the customer experience through enhanced business processes.

The Takeaway for Professionals

Professionals armed with the knowledge of Value Added Analysis hold a key advantage. They are equipped to identify not just where the business excels, but also where it can rise to new heights. Understanding this technique is not just about improving processes—it’s about adopting a mindset that prioritizes value creation at every turn.

Stepping into Fast Mode

Grasping the intricacies of Value Added Analysis is just the beginning. The true journey begins with applying this knowledge in real-time, with real-world complexities. For those looking to fast-track their expertise, BPM Fast Mode Courses offer a gateway to mastery—transforming understanding into action, and action into value.

As we’ve seen, the merits of Value Added Analysis are clear. It’s a illumination in the complex world of BPM, guiding professionals towards smarter, customer-focused decisions. Those who master it not only become more valuable assets to their organizations but also to the customers they serve. To join the ranks of these BPM experts, consider enrolling in a course that propels you into the fast mode of value creation. Because in the end, it’s the added value that defines success.

Wow that was odd. I just wrote an extremely long comment but after I clicked submit my comment didn’t appear. Grrrr… well I’m not writing all that over again. Anyhow, just wanted to say fantastic blog!

Sorry about that. We are back to work on this blog with a new team member. So, we will reply and aprove more quickly.

Thank you for your articles. http://www.hairstylesvip.com They are very helpful to me. Can you help me with something?

Of course. What can I do for you?