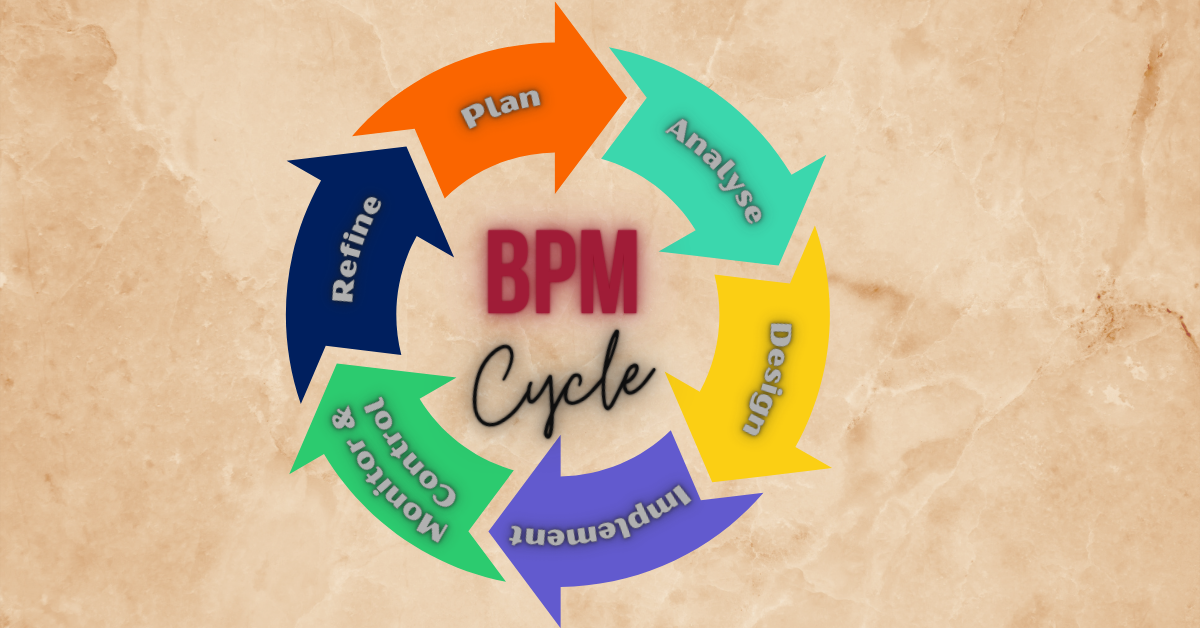

Mastering Continuous Improvement: Navigating the BPM Cycle for Organizational Excellence

Business Process Management, or BPM, is the state of art of implementing continuous improvement within an organization’s process. The BPM cycle is the roadmap for this art, consisting of six essential stages.

Imagine the first stage as the blueprint phase where organizations lay out their strategic vision. It’s about deciding how to manage their processes or improve existing ones.

Once the plan is in place, it’s time for the second stage: the diagnostic analysis. Think of it as the health check-up for business processes, diagnosing areas that need a change.

The third stage is the Design phase. Here, based on the analysis, we reach out a better layout for the process, drawing up solutions to the diagnosed problems.

Stage four is where action happens – the Implementation. The organization rolls out the improvements, transforming the theoretical into the practical.

But the job isn’t done yet. With BPMS tools, stage five involves monitoring and controlling the processes. It’s the stage where you make sure everything runs like a well-oiled machine.

Finally, we reach the Refinement phase, the critical point where processes are polished to perfection. And then, the cycle recommences, restarting the continuous improvement once more.

For professionals, becoming proficient in BPM goes beyond personal advancement; it equips you to facilitate the growth and success of others. This expertise not only distinguishes you but also makes you a critical asset in a constantly changing business environment.

Planning – Core to BPM Efficacy

Every BPM cycle starts with laying down a strategic framework. It’s about understanding the company’s vision and aligning the business processes to march towards that goal. In this phase, the organization identifies its primary and secondary processes and develops a comprehensive management plan. By the end of this stage, there should be a clear roadmap for process improvement initiatives.

Addressing Internal Issues and Perceptions

Addressing Internal Issues and Perceptions

Within the strategic planning phase, acknowledging internal issues as perceived by stakeholders and customers is vital. Stakeholders may identify inefficiencies and obstacles that are not immediately apparent to the leadership team. Similarly, customer feedback can reveal gaps between service delivery and customer expectations. Addressing these issues early in the planning process ensures that improvement efforts are customer-centric and stakeholder-informed.

Top-Down Support – The Board Director Statements

Top-Down Support – The Board Director Statements

The endorsement and active support from the governance – a top-down approach – are fundamental for the effectiveness of BPM. Leadership commitment provides the authority and resources necessary for change management and sets the tone for an organizational culture receptive to continuous improvement.

Bottom-Up Perspective – Operational Team Buy-In

Bottom-Up Perspective – Operational Team Buy-In

In other hand, gaining accreditation from the operational team represents the bottom-up approach. This is where the input from those who work on the front lines feeds into the planning process, ensuring that the proposed changes are practical and grounded in the day-to-day reality of business operations.

Empowering these team members fosters a sense of ownership and aids in the adoption of new processes.

Process Mapping Necessity

Process Mapping Necessity

Process mapping is a foundational tool in BPM. It provides a visual representation of the current state of business processes, serving as a baseline for identifying inefficiencies and areas for improvement. This clear visualization aids in comprehending workflows and facilitates targeted enhancements.

Categorization of Processes

Categorization of Processes

Distinguishing processes as primary or secondary is an important step. Primary processes are directly related to the value chain, impacting the customer’s experience and satisfaction. Secondary processes, while supportive in nature, are vital for the seamless execution of primary processes. Both categories need evaluation for overall operational efficiency.

Prioritization of Improvements

Prioritization of Improvements

Prioritizing improvements is based on potential value addition. This step involves assessing which changes will bring about the most significant enhancements in terms of customer satisfaction, cost reduction, or revenue generation.

Reporting and Progression to the Next Phase

Reporting and Progression to the Next Phase

Documenting the findings with comprehensive reports ensures that all stakeholders are on the same page and facilitates the transition to the diagnostic analysis phase. These reports should highlight key opportunities for improvement and set the stage for the in-depth analysis that follows.

Example

In the strategic planning stage of BPM within a car dealership, the engagement of stakeholders would involve soliciting input from various departments – sales, service, parts, and administration. Stakeholders might identify internal issues like the length of time to complete a sale or the inefficiency in inventory management.

Customer feedback is important to remark the need for a more streamlined purchasing process or better after-sales support.

Confronting resistance to change would be addressed by illustrating to the sales team, for example, how a new CRM system could make their day-to-day interactions with customers more manageable and increase their sales through better lead management. By demonstrating potential improvements in their workflow, employees can see the tangible benefits that process improvements can bring, thereby reducing resistance.

The support from senior management would be crucial, that because it could be needed to authorize the resources and reinforce the importance of BPM initiatives. This top-down support might manifest as an executive sponsor for the BPM project, providing visibility and strategic alignment.

Similarly, a bottom-up approach would involve service technicians or sales associates providing feedback on the practical challenges they face, such as complicated paperwork or inefficient lead tracking, which would be invaluable in performing the strategic planning.

For a car dealership, categorizing processes as primary or secondary helps in understanding which processes directly touch the customer and which support internal operations. Sales procedures, test-drive protocols, and service quality would be primary processes because they directly affect the customer experience. Inventory control and scheduling, while crucial, are secondary processes because they are internally facing, though they indirectly impact customer satisfaction.

In prioritizing improvements, the dealership might decide to first focus on the sales process, which could directly increase revenue and improve customer satisfaction. If customers have expressed dissatisfaction with the time it takes to purchase a car, the dealership might look at simplifying paperwork as a high-priority improvement.

Reporting to stakeholders would then outline the feedback, resistance encountered, support required, and the prioritized improvements, setting the stage for a detailed diagnostic analysis of each identified area. It would explain how, by enhancing these processes, the dealership could not only increase efficiency but also improve the overall buying experience, leading to higher customer satisfaction and loyalty.

Diagnostic Analysis

In the diagnostic analysis phase, involving stakeholders is critical. Their engagement ensures that those who will be impacted by changes in processes are part of the solution from the beginning. This inclusivity fosters collaboration, increases buy-in, and enhances the quality of input for process improvements.

Diagnostic Analysis – The Business Health Check

Diagnostic Analysis – The Business Health Check

Once the strategy is in place, it’s time to diagnose. This stage is the analytical backbone of the cycle, assessing each business process to pinpoint successes and areas in need for improvement. It’s a deep dive into current operations to understand the ‘AS-IS’ state – what’s working well and what’s not. This analysis forms the bedrock of the actionable insights that will feed into the next phase.

Utilizing Analysis Tools for Improvement Identification

Utilizing Analysis Tools for Improvement Identification

The diagnostic analysis phase employs a variety of analytical tools to uncover areas needing improvement. The root cause analysis tool helps to drill down to the underlying reasons for process issues, preventing superficial fixes and promoting long-term solutions. By examining the value chain, the organization can evaluate each step in a process for its contribution to the overall customer value, highlighting non-value-adding activities ripe for optimization or elimination.

Capacity and demand analysis is used to balance resources with customer needs, ensuring that the company can meet demand without excessive overcapacity or underutilization. Key Performance Indicators (KPIs) provide a quantifiable measure of process effectiveness and efficiency, tracking progress and signaling when processes are deviating from desired outcomes.

The lean philosophy, with its focus on waste reduction and process streamlining, serves as a guiding principle to identify and eliminate redundancies and inefficiencies, thereby enhancing process flow and maximizing value to the customer.

Process Modeling with BPMN and the AS-IS Model

Process Modeling with BPMN and the AS-IS Model

Creating an AS-IS model using Business Process Model and Notation (BPMN) provides a graphical depiction of the current processes. BPMN’s standardized set of symbols and rules for process modeling facilitates clear communication and understanding among stakeholders. This graphical language translates complex process steps into a visual map, making it easier to identify disconnects, bottlenecks, and redundancies.

Effective Meeting Strategies

Effective Meeting Strategies

Conducting various types of meetings and brainstorming sessions is imperative for leveraging collective intelligence. These collaborative sessions should be structured to encourage open communication, generate new ideas, and converge on practical solutions.

Overcoming Resistance to Change

Overcoming Resistance to Change

Change resistance is common, especially among individuals who are accustomed in their routines. To overcome this, it is essential to communicate the benefits of process improvements clearly and to establish a narrative that should lead to better operational outcomes. Demonstrating quick wins and involving employees in solution creation can help in building opportunity for change.

Overcoming Information Gathering Challenges

Overcoming Information Gathering Challenges

Obtaining information can be challenging, particularly from established processes and veteran employees who may be used to the status quo. A systematic approach to discover information, such as targeted interviews or observational studies, is essential to expose tacit knowledge and integrate it into the improvement plan.

The AS-IS Analysis Report

The AS-IS Analysis Report

The culmination of this phase is the AS-IS analysis report. This document synthesizes the insights gained from the use of various analytical tools and BPMN modeling. It presents a detailed view of the current state of processes, documenting the existing workflow, issues, and inefficiencies.

This report is critical as it sets the benchmark against which all future improvements will be measured and provides a factual basis for the Design phase of the BPM cycle. It ensures that the organization has a clear understanding of what is happening now to inform what should happen in the future.

Example

In the context of a car dealership, the diagnostic analysis phase would apply specific tools and methodologies to study each aspect of the dealership’s operations.

Employing Root Cause Analysis

For instance, if the dealership notices a trend of declining sales despite an increase in showroom traffic, root cause analysis might reveal that customers feel exausted by the variety of choices and financing options.

Value-Chain Analysis

A value-chain analysis could show that certain steps within the sales process, like the financing approval or vehicle registration, are overly time-consuming and not adding significant value from the customer’s perspective.

Capacity and Demand Assessment

Capacity and demand analysis would help the dealership match the number of sales representatives to customer step out at different times, ensuring customers receive prompt service without overstaffing during slower periods.

KPI Tracking

The dealership might set KPIs related to sales conversion rates, average time spent per sale, and customer satisfaction scores post-purchase. Monitoring these KPIs would highlight performance against objectives and signal areas for improvement.

Lean Philosophy Integration

By integrating lean principles, the dealership could identify waste in the process—like unnecessary steps in the documentation or redundant inventory checks—that slows down the car buying process.

Modeling with BPMN

Using BPMN, the dealership maps out its AS-IS model. This would visually represent the current sales process, from the initial customer greeting to the final handover of keys. Any identified bottlenecks, like a lengthy credit check, become targets for redesign.

The AS-IS Analysis Report

The AS-IS analysis report for the dealership would detail the findings from these analyses. It might point out that while customers are initially eager, the momentum stalls at the financing stage, suggesting a need for a more efficient financial approval process. The report would also highlight how better managing sales representatives’ time could improve customer experience and potentially increase sales.

This report feeds directly into the next phase, where the dealership would design improved processes to address these identified issues—setting the scene for enhancing customer satisfaction and optimizing sales efficiency.

Process Design – Drafting the Future

With the data from the diagnostic analysis, we enter the design stage. Here, the organization outlines a ‘TO-BE’ process modeling – a blueprint of what the ideal process should look like. This stage is about solving the problems identified in the diagnostic phase with innovative solutions, ensuring the new design aligns with the strategic goals set out in the first phase.

Leveraging the AS-IS Report for Improvement

Leveraging the AS-IS Report for Improvement

The design process begins by studying the AS-IS report in depth. Analysts focus on the highlighted areas of improvement, particularly those associated with excessive time consumption, reworks, and errors. The goal here is to lean out the process by reducing non-value-adding activities and simplifying the steps involved.

Focusing on Future Control and Monitoring

Focusing on Future Control and Monitoring

As processes are selected, it is crucial to design them with future monitoring and control in mind. This means creating workflows that are not just efficient but also measurable and transparent for ongoing management.

Developing the TO-BE Model

Developing the TO-BE Model

The TO-BE model emerges as the desired future state. It is a detailed representation of the optimized process, capturing the anticipated improvements in flow and efficiency. This model is constructed with an eye towards achieving leaner operations, reducing redundancies, and improving overall process quality.

Process Simulation

Process Simulation

Before finalization, the TO-BE model is often subjected to simulation. This virtual run-through predicts the performance of the redesigned process, allowing analysts to identify any potential issues before implementation.

The TO-BE Report

The TO-BE Report

The TO-BE report contrasts the future state with the current AS-IS model, demonstrating the expected improvements. It is a comprehensive document that outlines the benefits of the redesigned process, including time savings, error reduction, and enhancements in quality control.

Validation Meetings and Prototypes

Validation Meetings and Prototypes

Validation meetings and prototypes are critical in this phase. Stakeholders are presented with a prototype or a detailed walkthrough of the TO-BE model. These sessions validate the redesign and help stakeholders visualize the future state, facilitating buy-in and facilitating the transition away from familiar routines.

Company-Wide Integration and Value Addition

Company-Wide Integration and Value Addition

Throughout the design phase, the alignment of the new process with company-wide operations is assessed to ensure integration. The process design not only looks at departmental improvements but also at the cross-functional alignment that adds value to the entire organization.

In conclusion, the Process Design phase is pivotal, as it transitions the theoretical insights from the AS-IS report into a tangible and optimized TO-BE model. This phase lays the basis for the actual changes that will drive the organization forward, emphasizing efficiency, integration, and value creation.

Example

In redesigning the financing process, the dealership opts to integrate a new financing software that automates credit checks and loan approvals. This change aims to reduce processing times significantly and introduces a more optimized workflow. For vehicle delivery, a simplified checklist and a scheduled delivery system are designed to ensure timely and error-free handovers to customers.

Creating the TO-BE Model

The TO-BE model for the dealership shows a renovated sales process where customers experience minimal wait times for financing and a uncomplicated vehicle delivery. This model also includes checkpoints for quality control, such as customer satisfaction surveys post-purchase and real-time monitoring of financing approval times.

Simulating the Process

Before implementation, the dealership simulates the new sales process using the TO-BE model. This simulation helps in identifying any unexpected bottlenecks, particularly in peak sales periods, and allows for adjustments to be made preventively.

Developing the TO-BE Report

The TO-BE report outlines the expected improvements: financing approval times are projected to decrease by 50%, and vehicle delivery errors are expected to reduce significantly. This report clearly illustrates the benefits of the process redesign, from both operational efficiency and customer satisfaction perspectives.

Validation Meetings and Prototypes

The dealership organizes validation meetings where stakeholders, including salespeople, finance officers, and service managers, are walked through the new process. Prototypes of the new financing software interface and the delivery schedule system are demonstrated to ensure that all team members understand their roles in the optimized process.

Ensuring Company-Wide Integration

The TO-BE model’s success hinges on its integration into the dealership’s overall operations. The redesign considers not just the sales department but also how these changes impact the service and parts departments, ensuring that the new process enhances the dealership’s value proposition to its customers.

In essence, by applying the principles of the Process Design phase, the dealership crafts a future where sales processes are not only faster and more efficient but also aligned with the goal of delivering exceptional customer service. This strategic redesign sets the stage for the implementation phase, where these plans move from paper to practice.

Implementation – Turning Plans into Action

This is the ‘do’ phase. The organization takes the designs and puts them into practice. It involves rolling out the changes, which could be anything from tweaking a step in a process to introducing new technology. The implementation phase is all about action, making the necessary adjustments to improve efficiency and effectiveness.

The Implementation phase is where the strategic vision wondered in the Process Design phase takes physical shape. It’s the critical transition from theoretical models to real-world execution.

Executing Proposed Changes

Executing Proposed Changes

The importance of implementing the changes proposed cannot be inflated. It’s here that the dealership’s operational enhancements are actualized, directly impacting efficiency, customer satisfaction, and ultimately, profitability. This phase involves detailed planning to ensure changes are rolled out smoothly and effectively.

Upgrading Operational Systems

Upgrading Operational Systems

Frequently, the implementation of redesigned processes necessitates the upgrading or replacement of existing ERP (Enterprise Resource Planning) systems. For the car dealership, this might mean adopting a new ERP system better suited to integrate the new financing approval process and vehicle delivery system, ensuring these processes are seamlessly managed and tracked.

Employing BPMS for Process Management

Employing BPMS for Process Management

Business Process Management Systems (BPMS) emerge as a powerful ally in implementing process changes. A BPMS can directly incorporate the TO-BE model designed in BPMN, providing a structured platform for managing the redesigned processes. This system enables the dealership to automate workflows, ensuring that the new processes are followed as intended.

Integration Capabilities of BPMS

Integration Capabilities of BPMS

A key feature of modern BPMS tools is their ability to integrate with other existing systems and databases, either through direct access or via web services. This capability is crucial for the dealership, allowing for the seamless flow of information between the new BPMS and other operational tools, such as the inventory management system or customer relationship management software. This integration ensures that data is consistent and accessible across all platforms, enhancing operational efficiency.

Setting the Stage for Monitoring and Controlling

Setting the Stage for Monitoring and Controlling

The implementation of the new processes and systems sets the fundamentals for the next phase of the BPM cycle: Monitoring and Controlling. By integrating the redesigned processes with a BPMS, the dealership not only optimizes its operations but also gains valuable insights into process performance. The BPMS allows for real-time monitoring and generates data that can be used to measure the effectiveness of the new processes against the KPIs established in earlier phases.

In conclusion, the Implementation phase is where the dealership’s commitment to process improvement is tested and realized. By thoughtfully applying the changes proposed, upgrading systems as necessary, and leveraging the capabilities of BPMS, the dealership moves closer to achieving its strategic objectives. The successful execution of this phase ensures that the dealership is well-positioned to monitor, control, and continuously improve its processes, driving sustained business growth.

Example

In the car dealership example, the dealership moves forward with implementing the redesigned sales process and vehicle delivery system outlined in the TO-BE model.

Executing Proposed Changes

The dealership begins by rolling out the new financing approval software. This software, selected for its efficiency and compatibility with the dealership’s needs, is introduced to the finance team through a series of training sessions. Similarly, the streamlined vehicle delivery process is implemented, involving a new scheduling system to ensure timely deliveries.

Upgrading Operational Systems

To support these changes, the dealership upgrades its ERP system to a more robust solution that can seamlessly integrate with the new financing software and the delivery scheduling system. This upgrade is crucial for maintaining a unified database that reflects real-time inventory, customer interactions, and financial transactions.

Employing BPMS for Process Management

A BPMS tool is adopted to manage and automate the redesigned processes. This tool is configured to mirror the TO-BE model, ensuring that the process workflows precisely as designed. The BPMS becomes the central hub for process execution, monitoring, and reporting, offering features like automated alerts for process deviations and dashboards for performance tracking.

Integration with Existing Systems

The BPMS tool is integrated with the dealership’s upgraded ERP system and other operational tools through web services. This integration ensures that data flows smoothly across systems, providing a unified view of operations. For example, when a vehicle is sold, the inventory system is automatically updated, and the financing process is triggered in the BPMS, ensuring that all steps are followed according to the new design.

Preparation for Monitoring and Controlling

With the implementation of the new processes and systems, the dealership is now equipped to monitor and control its operations more effectively. The BPMS tool provides real-time insights into the financing approval times, vehicle delivery schedules, and customer satisfaction levels. These metrics will be closely watched to assess the impact of the changes and identify areas for further refinement.

This practical execution of the Implementation phase demonstrates how the dealership takes the concepts and plans from the Process Design phase and turns them into operational realities.

By carefully managing the rollout of new systems, training staff on new procedures, and ensuring seamless integration between tools, the dealership sets itself up for improved efficiency, better customer service, and increased profitability. The successful implementation also lays the foundation for the continuous monitoring and controlling of processes, enabling ongoing improvement and adaptation to changing market conditions.

Monitoring and Controlling – The Navigational Compass

With the new processes in place, the fifth stage is about keeping a close eye on them. Using BPMS tools, the organization tracks performance, ensuring that the implemented changes achieve the desired outcomes. This phase is crucial for maintaining control over the processes and ensuring they stay aligned with the strategic vision.

In the Monitoring and Controlling phase, the primary objective is to ensure that the newly implemented processes are not only operating as intended but are also delivering the desired outcomes, particularly in terms of customer satisfaction. This phase is critical for the ongoing success of the BPM cycle, as it provides the feedback necessary for continuous improvement.

The Role of Business Activity Monitoring (BAM)

The Role of Business Activity Monitoring (BAM)

One of the key tools in this phase is Business Activity Monitoring (BAM), a feature of many Business Process Management Systems (BPMS). BAM allows for the real-time observation of processes, offering immediate insights into their performance. This capability is invaluable for ensuring customer satisfaction by enabling quick intervention when processes deviate from expected performance levels.

Parameterization of Processes in BPMS

Parameterization of Processes in BPMS

A significant advantage of using BPMS is its ability to be parameterized with expected times for each activity within a process. This feature allows for the precise tracking of how long each step should take versus how long it is actually taking. When processes exceed these expected times—indicating delays or inefficiencies—they are highlighted, or shined, making it easy for process managers to identify and address issues promptly.

Comprehensive Process Overview

Comprehensive Process Overview

BPMS provides a comprehensive overview of all processes, integrating data across different stages and activities. This holistic view is crucial for understanding how individual parts of the process impact the whole. By making this information accessible to all involved parties, BPMS fosters a culture of transparency and collective responsibility for process performance.

Sharing Indicators for Improvement

Sharing Indicators for Improvement

Moreover, BPMS facilitates the sharing of performance indicators with all stakeholders. These indicators, which are derived from the real-time data collected by BAM, form the basis for identifying areas of improvement. They highlight not just inefficiencies but also opportunities to enhance process outcomes further.

Foundation for the Refinement Phase

Foundation for the Refinement Phase

The insights gained during the Monitoring and Controlling phase lay the groundwork for the final phase of the BPM cycle: Refinement. The data collected through BPMS, particularly the performance indicators, are analyzed to determine what adjustments are necessary to optimize processes. This continual loop of feedback and improvement ensures that the organization remains agile and responsive to both internal and customer needs.

In this way, the Monitoring and Controlling phase is central to maintaining the integrity and effectiveness of the BPM cycle. By leveraging tools like BPMS and features such as BAM, organizations can ensure that their processes are continually aligned with their goals of efficiency, effectiveness, and, most importantly, customer satisfaction.

Example

Continuing with our car dealership example, let’s see how the Monitoring and Controlling phase is implemented using the principles described.

After rolling out the new financing approval process and the streamlined vehicle delivery system, the dealership begins the critical work of monitoring these processes to ensure they meet the intended objectives, particularly enhancing customer satisfaction.

Implementing Business Activity Monitoring (BAM)

The dealership employs a BPMS with BAM capabilities to monitor the new processes in real-time. For example, BAM tracks how long each financing approval takes, comparing actual times against the benchmarks set during the design phase. If a particular approval process is taking longer than expected, alerts are triggered, allowing the finance team to intervene immediately, identify the cause of the delay, and take corrective action.

Parameterization of Processes

The BPMS is parameterized with expected completion times for each step of the vehicle delivery process. This parameterization helps in quickly identifying when a vehicle preparation and delivery is falling behind schedule, allowing the delivery team to adjust their workflow or allocate additional resources to ensure timely completion.

Providing a Comprehensive Overview

Through the BPMS dashboard, the dealership management has a comprehensive overview of the entire sales process, from initial customer inquiry to final vehicle delivery. This overview includes real-time data on the performance of each process, highlighting areas of efficiency and bottlenecks.

Sharing Performance Indicators

The dealership makes performance indicators available to all employees involved in the sales and delivery processes. Regular meetings are held to discuss these indicators, fostering a culture of continuous improvement. Employees are encouraged to share their insights and suggestions for enhancing process performance, leveraging their direct experience with customers and day-to-day operations.

Laying the Groundwork for Refinement

The insights percepted during this phase, particularly those related to process delays, customer feedback, and the effectiveness of the interventions, will be crucial for the next Refinement phase. The dealership plans to use this data to further optimize the financing and delivery processes.

For instance, if customer feedback indicates that the vehicle delivery process is smooth but the financing approval still poses challenges for some customers, the dealership may focus on further streamlining the financing process.

This practical application of the Monitoring and Controlling phase demonstrates how the car dealership ensures that its newly implemented processes are delivering the desired outcomes. By actively monitoring process performance and being prepared to make immediate adjustments, the dealership not only enhances customer satisfaction but also positions itself for ongoing improvement and success.

Refinement – The Cycle of Improvement

Finally, refinement is where the organization takes stock of the new processes. It’s a time to refine and optimize, making adjustments based on feedback and performance data. This stage closes the loop of the BPM cycle, but it’s also a launching point – as one refinement phase ends, the insights gathered lead back to strategic planning, and the cycle begins anew.

The Refinement phase is where the iterative nature of the Business Process Management (BPM) cycle proves its worth. This phase emphasizes the critical importance of continuous evaluation and optimization of processes to ensure they remain aligned with business objectives and market demands.

The Essence of Refinement

The Essence of Refinement

Refinement is not just about simply modifying what exists; it’s about taking a step back, evaluating the outcomes of the Monitoring and Controlling phase, and determining how the processes can be further optimized. It acknowledges that business environments are dynamic, and what works today may not be the best solution tomorrow. Thus, refining processes ensures they evolve in tandem with business needs and customer expectations.

Relation to the PDCA Cycle

Relation to the PDCA Cycle

The Refinement phase has a direct correlation with the Plan-Do-Check-Act (PDCA) cycle, a core concept of continuous improvement philosophies like Lean and Six Sigma. PDCA is a cyclic approach for achieving continuous improvement in processes and products.

In the context of BPM, the Refinement phase acts similarly to the ‘Act’ step in PDCA, where the insights gained from monitoring (Check) lead to actions (Act) that initiate a new cycle of planning and implementation (Plan and Do).

Continuous Improvement and Business Success

Continuous Improvement and Business Success

Continuous improvement is not just an operational strategy; it’s a cornerstone of business success. In today’s fast-paced and ever-changing business environment, the ability to rapidly adapt and improve processes can be the difference between thriving and merely surviving. Continuous improvement through BPM ensures that processes not only meet current standards but are also poised to adapt to future challenges and opportunities.

Leveraging BPMS for Easier Refinements

Leveraging BPMS for Easier Refinements

The use of a Business Process Management System (BPMS) significantly facilitates the Refinement phase. With the process models already mapped and implemented within the BPMS, making adjustments is both efficient and effective. Changes to the TO-BE model can be directly updated in the BPMS, allowing for rapid deployment of refinements. This capability reduces the time and resources needed to implement changes, enabling a more agile response to process improvement needs.

Furthermore, BPMS tools often come with analytical capabilities that provide invaluable insights into process performance, identifying not just areas of improvement but also predicting the potential impacts of proposed changes. This predictive analysis helps in making informed decisions on which refinements are likely to yield the best outcomes.

Example

Returning to our car dealership example, let’s see how the Refinement phase is enacted, demonstrating its importance in the BPM cycle and its relationship to continuous improvement principles like the PDCA cycle.

After implementing the new financing approval process and the streamlined vehicle delivery system, and after a period of monitoring and controlling these processes, the dealership gathers a wealth of data and feedback. This information is now ready to be analyzed and used for refining the processes.

Analyzing Process Performance

The dealership reviews the performance data collected through the BPMS, noting areas where the actual outcomes did not meet the expected benchmarks. For example, while the new financing approval process significantly reduced approval times, customer feedback indicates that the communication around the status of financing could be improved.

Implementing Refinements

In response, the dealership decides to refine the process by implementing an automated notification system within the BPMS that updates customers about the status of their financing approval via email and SMS. This adjustment addresses the customer feedback directly and is expected to improve overall customer satisfaction.

PDCA Cycle Integration

This action represents the ‘Act’ step of the PDCA cycle. The dealership had Planned by designing the new processes, Done by implementing them, Checked by monitoring their performance, and now Acts by refining the process based on the insights gathered. This refinement will lead to a new cycle of planning (Plan), as the dealership looks to further enhance the customer experience and operational efficiency.

Continuing the BPM Cycle

With the refinements made, the dealership doesn’t stop there. Recognizing the value of continuous improvement, it prepares to run the BPM cycle again, starting with the strategic planning phase for the next set of improvements. This ongoing cycle ensures that the dealership remains adaptable and competitive, constantly seeking ways to better serve its customers and improve operations.

BPMS as a Catalyst for Change

Thanks to the flexibility of the BPMS tool, these refinements are made directly in the TO-BE model and quickly implemented into the dealership’s operational processes. The ability to swiftly update and deploy changes in the BPMS underscores the agility that such tools provide. This facilitates a culture of continuous improvement, where refinements are part of the business’s DNA, always striving for excellence in every aspect of operations.

Through this practical application of the Refinement phase, the dealership exemplifies how continuous evaluation and optimization of processes drive business success. The cycle of BPM, like to the PDCA cycle, ensures that the dealership not only meets the current needs of its customers but is also well-prepared to adapt to future challenges and opportunities.

Conclusion

In spinning up the BPM cycle with the Refinement phase, businesses underscore their commitment to continuous improvement. By systematically revisiting and refining processes, organizations can ensure they remain competitive, responsive to customer needs, and aligned with their strategic goals.

The BPM cycle, much like the PDCA cycle, is a testament to the belief that there is always room for improvement, and that the pursuit of excellence is a journey, not a destination. The use of BPMS tools in this journey not only streamlines the process but also embeds a culture of agility and adaptability within the organization.

Dive into the dynamic world of Business Process Management with our BPM Fast Mode courses. Tailored for professionals eager to master the art of continuous improvement, our courses equip you with the knowledge and tools necessary to transform business operations and drive success.

By enrolling in BPM Fast Mode, you’ll gain insights into:

Implementing strategic planning that aligns with business objectives

Conducting diagnostic analyses to identify areas for enhancement

Designing and Implementing process improvements using the latest BPM tools

Leveraging business Activity Monitoring for real-time operational insights

Embracing the PDCA cycle for sustained business agility and growth

-Whether you’re looking to streamline operations, enhance customer satisfaction, or lead your organization through transformational change, BPM Fast Mode offers the expertise you need to make it happen.

Take control of your professional future today. Sign up for BPM Fast Mode courses and embark on a journey to operational excellence and business leadership.

Elevate your career and your organization. Join BPM Fast Mode now.

Have you ever considered creating an ebook or guest authoring on other websites? I have a blog based on the same subjects you discuss and would love to have you share some stories/information. I know my readers would value your work. If you are even remotely interested, feel free to shoot me an email.

Hi there! Yes, we have this project. As we are elaborating new articles we decided to join all in a unique ebook. We are producing the third course “BPM implementations” where we will abord important concepts and techniques of BPM and process automations. But, thanks for your advise.

Greetings! This is my first comment here so I just wanted to give a quick shout out and say I genuinely enjoy reading through your posts. Can you recommend any other blogs/websites/forums that go over the same subjects? Appreciate it!

Take a look at the http://www.abpmp.org, they have a plenty of good info to share.

hey there and thank you for your information ?I have definitely picked up something new from right here. I did however expertise a few technical points using this web site, as I experienced to reload the web site many times previous to I could get it to load properly. I had been wondering if your hosting is OK? Not that I am complaining, but sluggish loading instances times will often affect your placement in google and could damage your quality score if ads and marketing with Adwords. Well I am adding this RSS to my email and can look out for a lot more of your respective intriguing content. Make sure you update this again soon..

Thanks for you advise. We are aware about some issues and this is new for us. We will look to solve properly.

Great beat ! I would like to apprentice while you amend your web site, how could i subscribe for a blog site? The account helped me a acceptable deal. I had been a little bit acquainted of this your broadcast provided bright clear concept

Go to our website at https://academyofmanaging.com/ and subscribe, so we can be more close and announce new articles and much more.